تاریخ بروزرسانی(Update Date): 24th February 2025

Introduction

Liquefied Petroleum Gas (LPG), as one of the most widely used energy sources in today’s world, plays a vital role in many industries and in people’s daily lives. From fueling vehicles to being used in household kitchens, this clean and affordable energy source has steadily gained its place among other fossil fuels. But this is just the beginning; behind this powerful energy source lies a complex story of production, transportation, and its diverse applications in various industries. Do you know how LPG is derived from raw resources? Or how it has managed to play a key role in the competitive energy world? This article aims to uncover the secrets of this valuable fuel and take a deeper look at its impact on the economy and human lives.

Advantages of LPG

Versatility and Wide Applications

LPG is used in three main areas: as a fuel for domestic, agricultural, and industrial use; as a petrochemical feedstock for producing products like rubber and plastic; and as a propellant in sprays. This variety of applications makes LPG one of the primary options for consumption in many industries.

Environmentally Friendly

Compared to other fossil fuels, especially coal and oil, LPG has lower emissions. With cleaner combustion and low carbon dioxide output, LPG is recognized as a greener option for reducing the impacts of climate change and air pollution. This characteristic has allowed many countries to use LPG to meet their greenhouse gas emission reduction goals.

Easy Access and Transportation

Unlike natural gas, which requires pipeline infrastructure, LPG can be easily stored and transported. This advantage has made LPG especially popular in remote areas and developing countries where access to extensive natural gas networks is limited.

Cost-Effective

Due to the abundance of LPG in oil and gas resources, its price is competitive compared to many other fuels. Additionally, its high energy efficiency and multifunctional applications allow consumers to produce and use more energy at a lower cost.

What is LPG?

Liquefied Petroleum Gas, abbreviated as LPG, is a mixture of propane and butane, with the proportion of each varying depending on its use and environmental conditions. (For example, we have LPG with a 50% propane and 50% butane ratio, and LPG with 70% propane and 30% butane.) LPG is produced as a byproduct of crude oil refining and natural gas extraction. After being separated from oil and natural gas, LPG can be liquefied under pressure, making it easy to transport and store.

Types of LPG

LPG (Liquefied Petroleum Gas) comes in various types, with the proportion of propane and butane adjusted based on usage and environmental conditions to improve efficiency and suitability for specific applications. These mixtures are designed to be optimized for different climates and for domestic, industrial, or transportation purposes.

In colder climates, mixtures with a higher percentage of propane (e.g., 70% propane and 30% butane) are typically used because propane more easily converts to gas at lower temperatures and provides the necessary energy with higher vapor pressure. These types of mixtures are used in open space heating, industrial equipment, and even gas-powered vehicles in colder regions.

Conversely, in warmer climates, the proportion of butane increases (for example, 60% butane and 40% propane), as butane performs better at higher temperatures and is also more cost-effective. This type of mixture is commonly used for household purposes like cooking and indoor heating, as well as in light commercial applications.

How is LPG Produced?

LPG (Liquefied Petroleum Gas) has both oil and gas origins and is a mixture of propane and butane, which are byproducts obtained from crude oil refining and natural gas processing. Contrary to popular belief, propane and butane are not initially produced separately and then combined; rather, these two gases are extracted as a mixture during the early stages of refining.

In the crude oil refining process, propane and butane are separated as a mixture during various stages such as atmospheric distillation, thermal and catalytic cracking, and oil reforming. Due to their similar physical properties, there is no need for complete separation. In fact, during these refining processes, light gases like propane and butane are extracted from crude oil as a combined form and stored and used as LPG.

The same process is observed in natural gas refining. Propane and butane, which exist as heavier hydrocarbon components in natural gas, are separated from methane and other lighter gases and obtained as LPG in their combined form from the start.

Storage and Transportation Conditions for LPG

Features of LPG Tanks

- Carbon steel and stainless steel are the most commonly used materials for LPG tanks due to their strength and high resistance to pressure, while aluminum and fiber composites are suitable for portable tanks and specific applications where lower weight and corrosion resistance are required.

- Tanks must be designed according to international and national standards that define the allowable storage pressure. For LPG, the required pressure is usually between 5 and 15 bars.

- LPG tanks are typically designed in a cylindrical shape to ensure uniform pressure distribution across the entire surface of the tank. This design increases the tank’s resistance to pressure.

- Tanks should be regularly inspected for the health of the body, valves, and fittings to detect and address any potential leaks, rust, or damage.

Safe Transportation Features for LPG

- Ensuring that the LPG transport vehicles meet all international standards and safety regulations is critical for secure transport.

- Employing skilled and trained drivers specialized in handling hazardous materials.

- LPG transport tankers must be made of durable materials (such as carbon steel or stainless steel) that can withstand high pressure.

- The tankers should be designed to withstand collisions or impacts. Mechanical guards must be installed over the valves and fittings to prevent damage.

- Pressure and gas level indicators are essential for continuous monitoring of the tanker’s status. These systems allow the driver or operator to respond quickly to any abnormal pressure fluctuations or gas level drops.

- The use of hazardous material labels is crucial (labels must comply with international standards and indicate that the cargo is LPG and dangerous).

Applications of LPG

Use as Fuel

The primary application of LPG is as a fuel. Due to its high calorific value, LPG is considered an efficient energy source. Compared to fuels such as coal and oil, LPG produces fewer emissions, making it an environmentally friendly option.

The energy and heat generated from LPG are used in various applications, including industrial, agricultural, transportation, and household uses. Some of these applications include:

- Heating and cooking in homes

- Steam production and heating in industries

- Fuel for gas-powered vehicles

- Drying agricultural products and temperature control in greenhouses and livestock farms

Use as Petrochemical Feedstock

LPG plays a significant role as a feedstock in the petrochemical industry and is considered one of the primary raw materials for petrochemical production. This fuel, which consists of propane and butane, is converted in petrochemical units into key chemicals such as ethylene, propylene, butadiene, and butylene. These base chemicals are then used to produce various products such as plastics, rubber, synthetic fibers, and other chemicals. Chemical processes such as thermal cracking or catalytic cracking are employed to break down the larger molecules of propane and butane into these valuable substances.

As a Propellant in Sprays

LPG is widely used as a propellant in aerosol industries. This colorless and odorless gas, due to its chemical and physical properties, is ideal for spray products such as pesticides, air fresheners, cosmetics, paint sprays, and food products. LPG is stored in liquid form under pressure in spray cans, and when used, it rapidly evaporates, propelling the active substance outward. This gas has replaced CFCs, which were banned due to their destruction of the ozone layer. LPG, with its lower emissions and high environmental compatibility, is a suitable choice for use as a propellant in sprays.

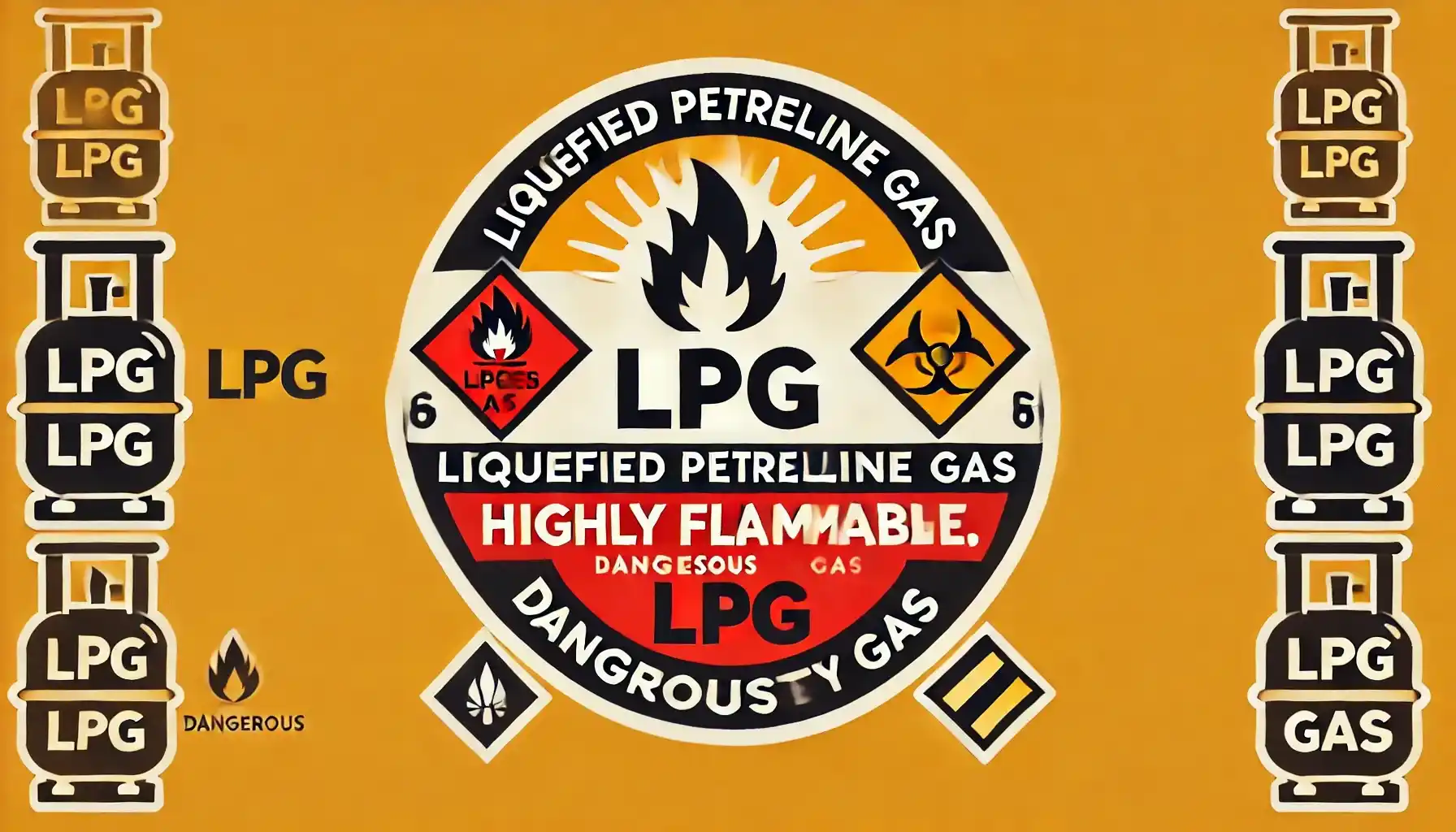

comparison between LNG (Liquefied Natural Gas) and LPG (Liquefied Petroleum Gas)

LNG (Liquefied Natural Gas) is essentially natural gas that has been liquefied through a cryogenic process, meaning it is cooled to extremely low temperatures. This process significantly reduces the volume of natural gas (by about 600 times), making its storage and transportation much more efficient.

Liquefied natural gas mainly consists of methane (CH₄), but it may also contain small amounts of other gases such as ethane, propane, and nitrogen. Due to its reduced volume and non-toxic, non-corrosive nature, LNG is a clean and popular fuel option for large industries and transportation, especially in areas where natural gas pipelines do not exist or access is limited.

Now, let’s look at the most important differences between these two fuels:

LPG is typically used in smaller industries, domestic applications, and light vehicles because of its easier storage and transportation capabilities and lower cost. It is suitable for lighter applications as it can be compressed under pressure without requiring complex storage equipment.

In contrast, LNG, with its higher energy density and the need for storage at extremely low (cryogenic) temperatures, is mainly used in large industries such as power generation, marine transportation, and heavy-duty transport fleets. The infrastructure required for LNG storage and transportation is more complex and costly due to the low temperatures and specialized tanks needed. However, because of its higher efficiency and lower emissions, LNG is better suited for large-scale industrial applications and long-distance transportation.

In summary, the key difference between these two fuels lies in their scale and type of use: LPG is used for lighter applications, while LNG is used for heavier industrial applications and long-distance transportation.

The Future of LPG

The future of Liquefied Petroleum Gas (LPG) looks promising due to its environmental benefits, high efficiency, and lower costs compared to other fossil fuels. With the growing global demand for cleaner fuels and renewable energy, LPG is set to play an important role as a versatile fuel in residential, industrial, agricultural, and transportation sectors. The expansion of energy infrastructure in developing countries and the use of LPG as a petrochemical feedstock will further drive its demand. Additionally, technological advancements in various industries will improve the efficiency of LPG usage. Overall, LPG will continue to be a sustainable and reliable energy source, maintaining its significant role in the global energy market.